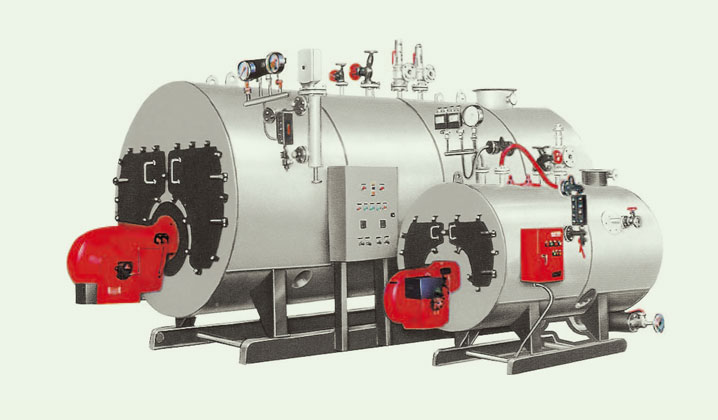

Description of Product WNS Series full-automatic oil (gas) – fired steam/hot water boiler made by Changzhou Soken is a horizontal triple-pass fire-tube boiler. It mainly is composed of boiler shell, boiler furnace, flue-gas reversing chamber and fire tube. The convection heat surface – coal economizer is rationally laid down in the rear. The funnel temperature conforms to the effluent discharge standard specified in national energy-saving requirement.

The boiler is suitable for use of light oil, heavy oil, natural gas, liquefied gas, urban gas, etc.

The product is designed with wetback structure and the structure of corrugated boiler furnace, thus reducing thermal efficiency of boiler and increasingsafety and service life of boiler.

With the unsymmetrical arrangement of heat surface, the stress and expansion of boiler is rational.

The rational heat surface ensures the good water circulation and heat exchange to make thermal efficiency reach the optimum status and increase the thermal efficiency of boiler.

With the burning chamber arranged in low position, the steam boiler has a wide safety range of water level and wide steam space either. The quality of steam is ensured.

With full butt weld wetback structure, it is avoided for back tube sheet to be damaged by high-temperature flue-gas to ensure the safety operation of boiler.

The advanced burner with world famous brand and fully-automatic control system is selected for use, which makes burning stable and operation convenient and running reliable.

Scope of product Steam Boiler: Evaporation discharge: 1 – 20 t/h; Pressure: 0.7 – 1.6MPa; Hot Water Boiler: Heating capacity: 0.7 – 14MW; Pressure: 0.7 – 1.25MPa.

Technical Data Table

Oil(Gas)-fired Steam/Hot Water Boiler

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-efficiency, Energy-saving, Environmental Protection

ChangZhou Soken continuously scales the heights and makes efforts for motivating the application technology of heat-carrier boiler to the new top.